As the commercial trucking industry evolves, fleet operators are increasingly focused on sustainable fleet solutions that align with strict EPA emissions compliance and long-term cost savings. One of the most effective—but often overlooked—ways to support these goals is through Diesel Particulate Filter (DPF) restoration.

Restoring diesel emissions system components like DPFs not only supports a circular economy in trucking, but also offers significant financial and operational advantages for fleets of all sizes.

Want to lower fleet maintenance costs without sacrificing performance? Learn how Ceramex can help.

Understanding DPFs and Their Role in Diesel Emissions Systems

Diesel Particulate Filters (DPFs) are a critical part of the modern aftertreatment system, capturing and storing soot and particulate matter from exhaust gases. This process is essential for reducing harmful emissions and meeting EPA Tier 4 and other stringent environmental standards.

Over time, DPFs become clogged with soot and ash, causing performance issues and increasing backpressure. While many fleets resort to replacement, DPF cleaning and restoration provides a more cost-effective, eco-friendly alternative.

Replacing a DPF can cost between $1,000 and $3,000 per unit—an unsustainable expense for large fleets. DPF restoration, on the other hand, significantly lowers costs while maintaining optimal performance.

The Economic Impact of DPF Restoration

1. Cost Savings for Fleet Operators

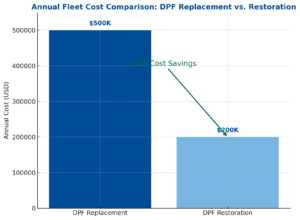

For fleet maintenance managers, diesel emissions system repair and replacement can represent a major portion of the annual budget. Across a fleet of dozens or hundreds of vehicles, new DPFs can lead to annual replacement costs of $200,000 to $500,000.

Choosing DPF restoration services can cut these costs by up to 60%, allowing budget reallocation to other key areas like labor, equipment, or safety programs.

- Large Fleet Costs: Annual filter replacement costs can exceed $500,000

- Restoration Savings: Up to 60% cost reduction by restoring filters instead of replacing them

Start saving now—request a custom quote for your fleet.

Replacing a DPF can result in days of lost productivity due to part sourcing and installation delays. In contrast, Ceramex’s DPF cleaning and restoration process typically takes only 24–48 hours, helping keep your fleet on the road.

- Downtime Reduction: Typical replacement = 3–7 days. Restoration = 1–2 days

- Fleet Impact: Reduced downtime improves delivery timelines and customer satisfaction

Looking to improve uptime? See how fast we can turn your filters around.

3. Environmental Sustainability & the Circular Economy

DPF restoration directly contributes to a circular economy in the transportation sector by reducing waste and conserving raw materials. Every restored filter is one less part sent to a landfill and one less that needs to be manufactured and shipped.

- Waste Reduction: Millions of DPFs are discarded annually—restoration helps change that

- Resource Conservation: Avoid the environmental costs of new part production and transport

Learn how restoration supports your sustainability goals.

Emissions Compliance: A Key Benefit of DPF Restoration

Staying compliant with EPA emissions standards and local regulations is non-negotiable for today’s fleets. A restored DPF effectively captures soot and particulate matter, ensuring compliance while avoiding hefty fines and penalties.

- Efficiency: Clean DPFs can reduce engine emissions by up to 90%

- Reliability: Consistent emissions system performance for inspections and reporting

Worried about emissions compliance? Let Ceramex help you pass every time.

Ceramex: The Leader in DPF Restoration Services

At Ceramex, we offer patented diesel filter restoration technology that restores filters to like-new condition. Our proprietary xpurge® and Veritex™ technologies provide superior results backed by data and proven field performance.

"The days of buying new replacement filters are over."

— Seth Browth, Strategic Partner at Ceramex North America LLC

With a 95% restoration efficiency rate, Ceramex’s advanced DPF cleaning process helps fleets save money, reduce downtime, and meet emissions standards—all while supporting sustainable practices.

Industry Trends & What the Future Holds

With new emissions regulations on the horizon—including EPA 2027—fleet operators are under increased pressure to find cost-effective, compliant solutions. DPF restoration services will play a vital role in bridging the gap between performance, sustainability, and budget.

- Market Growth: The DPF restoration industry is expected to grow 10–15% annually

- Stricter Regulations: Global standards are becoming more aggressive

- Fleet Strategy: Restoration allows reinvestment in safety, labor, and fleet modernization

Get ahead of EPA 2027. Partner with Ceramex today.

Frequently Asked Questions & Objection Handling

Will DPF restoration affect my vehicle’s warranty?

No. When performed correctly by a certified provider like Ceramex, restoration does not void your OEM warranty. We’re even recommended by major OEMs like Cummins.

How often should I restore my DPFs?

Most fleets restore DPFs every 200,000–400,000 miles. Let us help you determine your ideal interval.

What’s the difference between cleaning and restoration?

Cleaning removes surface soot. Restoration removes hardened ash, validates airflow, and returns the filter to OEM specifications using our proven patented equipment.

Isn’t buying new filters safer?

Not in most cases. 95% of filters can be restored safely and affordably. Contact us to evaluate your filter.

Conclusion: Why DPF Restoration Matters for Your Fleet

Choosing DPF restoration over replacement provides a triple benefit: reduced operational costs, improved fleet uptime, and a measurable contribution to environmental sustainability.

Here’s why your fleet should make the switch:

- Cost and Efficiency Gains – Save up to 60% on filter replacement and reduce downtime

- Sustainability Alignment – Reduce landfill waste and conserve resources

- Regulatory Compliance – Meet or exceed EPA emissions standards and avoid costly penalties

Don’t wait for a breakdown or inspection failure—start restoring your filters today.

Visit www.CeramexNA.com to learn more or Request a Quote.